What is the difference between Stainless Steel Grades?

Have you wondered what the difference is between grade 303, 304 and 316 stainless steel? Ultimately, it comes down to its resistance to corrosion, usage and suitability in various environments. Below, we suggest the most popular steel grade for each industry and the reasons why.

WDS have a varied range of stainless steel products but what's helpful to know is the difference between these and why you may pick one over another. Before we go into the technical answers to these questions we look at steel and stainless steel. Obviously both are very common metals but they vary in terms of strength, durability, hardness and cost. The main difference between the two is this, "invisible layer". Steel is created by adding iron to carbon, creating a hard material (sometimes we call this this mild steel). Stainless steel on the other hand has a low carbon and high chromium content forming a film on the surface to prevent it from staining.

Benefits of Stainless Steel

- Corrosion resistance

- Hygiene

- Ease of fabrication

- Fire and heat resistance

- Aesthetic appearance

- Long-term value

Grade 303

The main difference between grade 303 stainless steel and the remaining 300-series is the added sulphur which slightly reduces its corrosion resistance. However, it has increased machinability, in essence, how easily the metal can be cut, hence, the metal is often used for many fasteners, bushings, bearings and other small components. These require accurate machining due to the desired tolerances (discussed above).

Ideal for: manufacturing, aerospace, machinery, pipework and occasional wash down

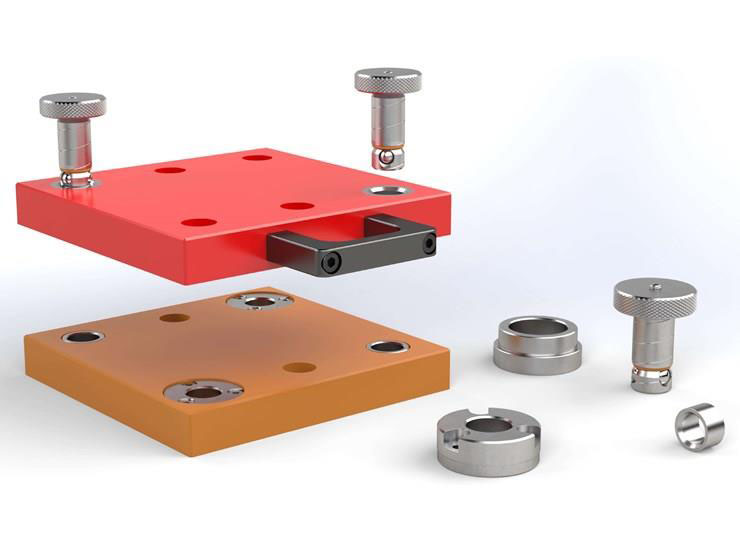

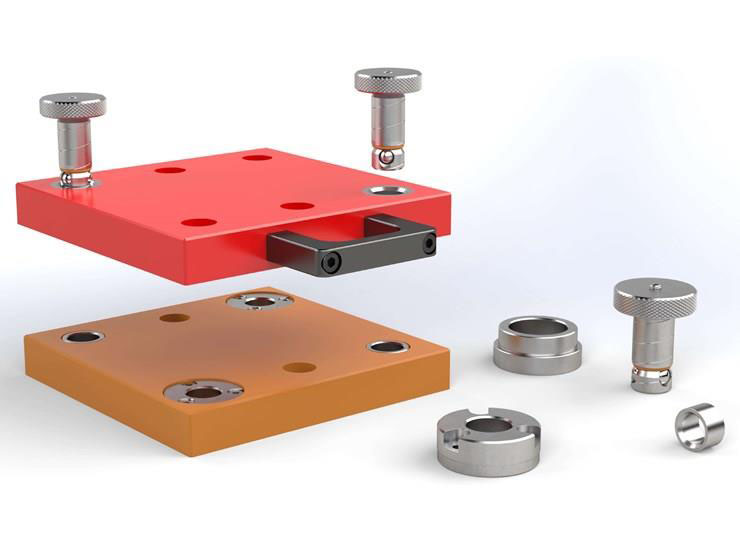

WDS products: studs, washers, nuts, swing bolts, threaded bars and knobs

Grade 304

More commonly known as the most popular and widely used, austenitic stainless steel due to its high amount of chromium and nickel. This metal can withstand mild corrosion from most oxidising acids thus is typically used for piping, heat exchangers, fasteners and commercial food processing equipment. The stainless steel's good formability allows for rapid welding abilities classing it as the most versatile in its series.

Ideal for: food and beverage, oil and gas, machinery and brewery

WDS products: toggle clamps, levelling feet, hand knobs, conveyor support tubes and handles

Grade 316

316 stainless steel, sometimes referred to as marine grade steel, has superior corrosion and pitting resistance to chlorides compared to grade 303 or 304 stainless steel. This version has an addition of molybdenum enforcing its strength at elevated temperatures, hence, its ideal use for pumps, valves and frequent wash down.

Ideal for: marine and offshore, food and beverage, medical and sterilisation

WDS products: T nuts, hinges, handles, springs, eye bolts, swivel pads and detent pins

Other Types of Stainless Steel

Grade 303, 304 and 316 are the most popular types of stainless steel used by WDS Components. However, there are additional types of stainless steel products which you can purchase from us such as Type 17-4. Whilst the aforementioned materials are austenitic classes of stainless steel, type 17-4 is martensitic which means it's magnetic. Additional features of the 17-4 are its high levels of strength and hardness as well as corrosion resistance and machinability, most similar to grade 304 stainless steel.

WDS products: quick release pins, ball lock shank, hoist rings and mount bushes

If you've got any additional questions or need extra support, please don't hesitate to contact us on 0333 043 5443 or just fill in our online Contact Form.